TECHNICAL SPECIFICATIONS

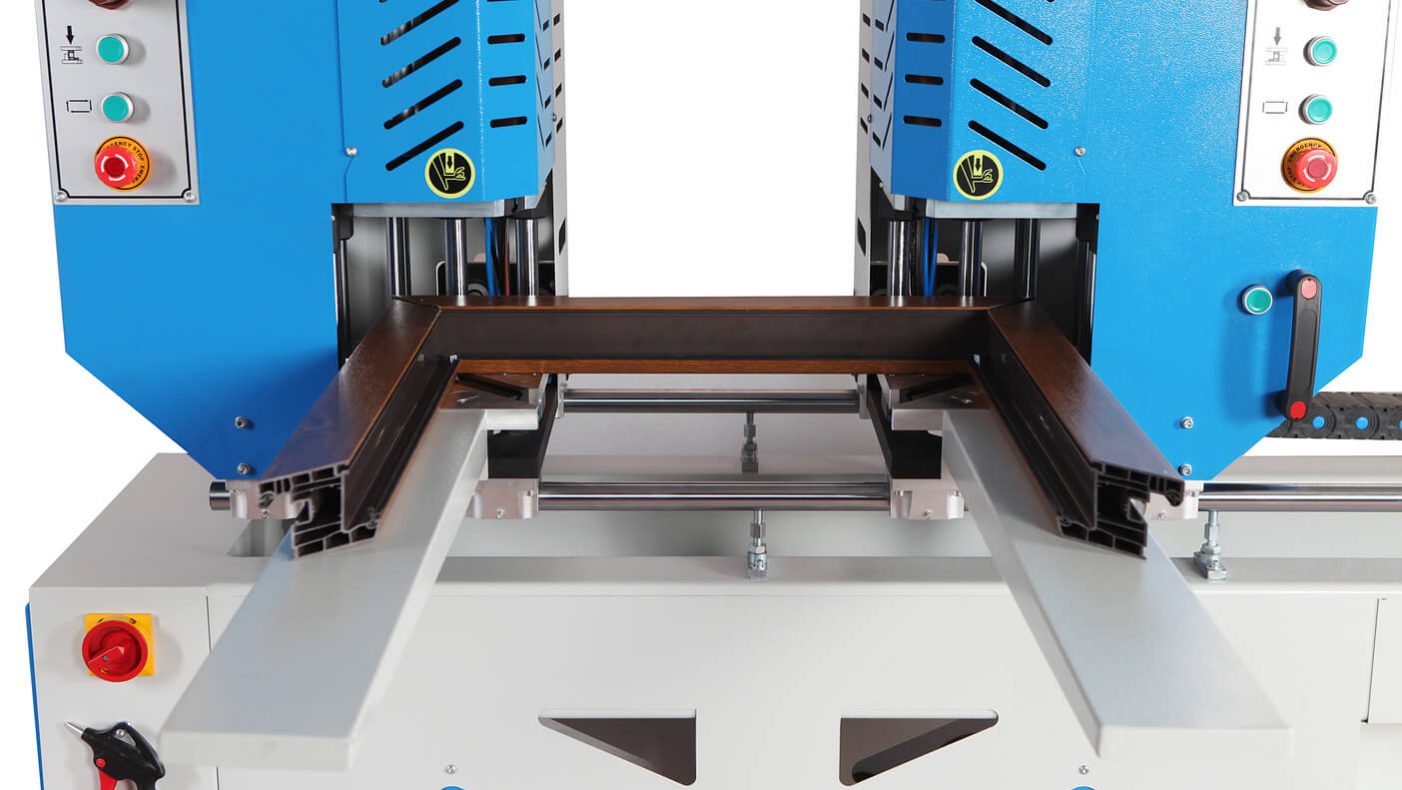

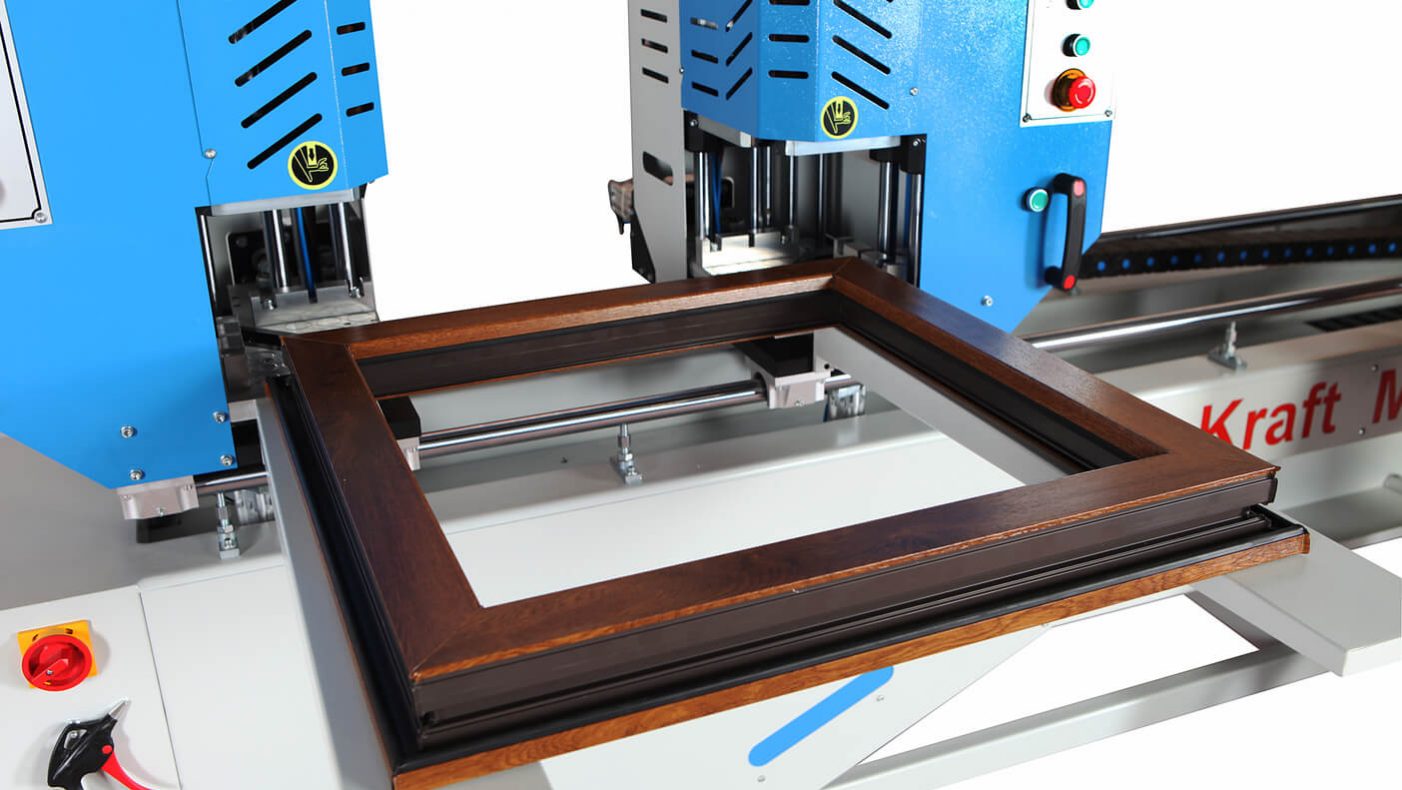

The double head pvc welding machine has designed to weld double corner of the PVC windows at the same time. Welding process is the most time consuming phase of a PVC window production. By using double head welding machine you can save time and energy and increase your daily production.

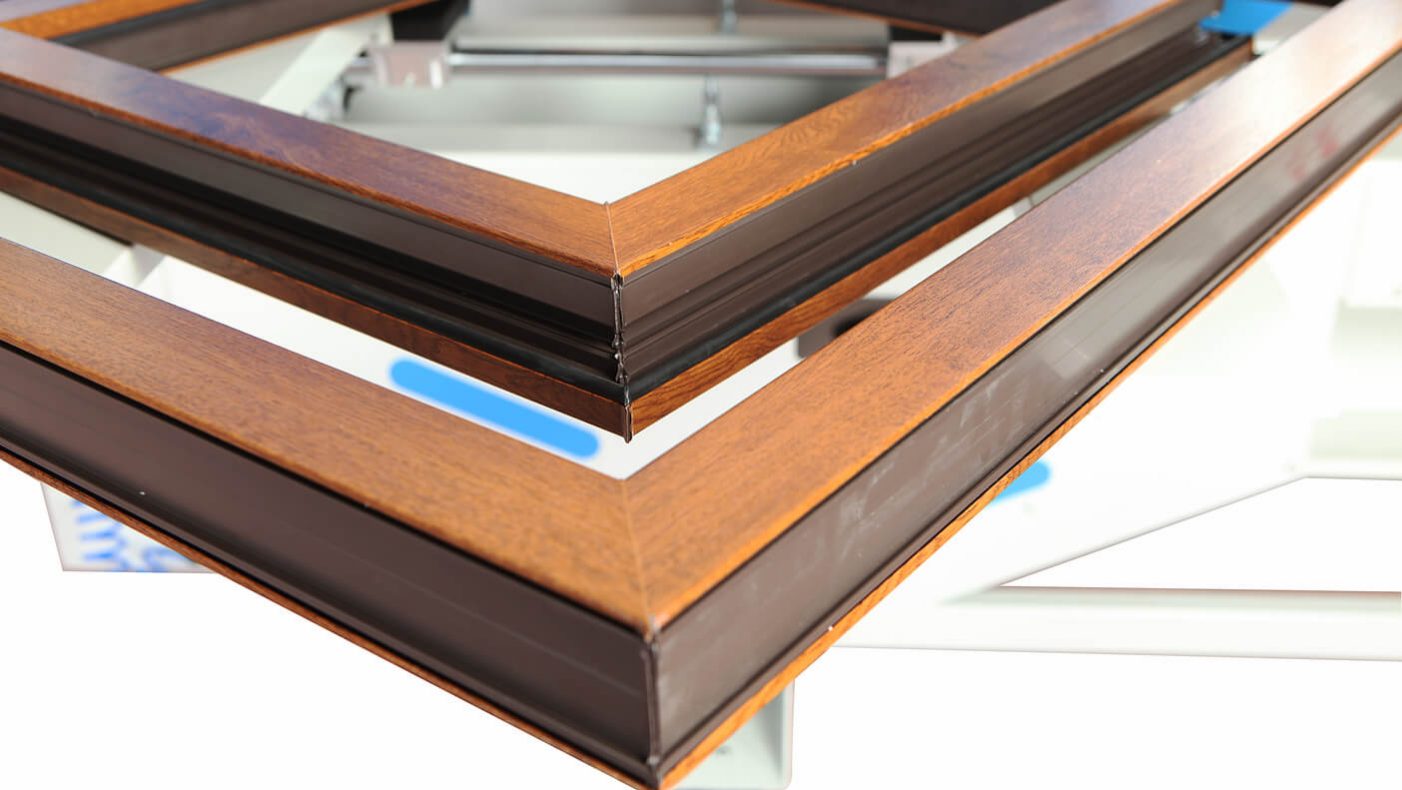

– Welds two corners of a pvc profile simultaneously with maximum durability in one operation.

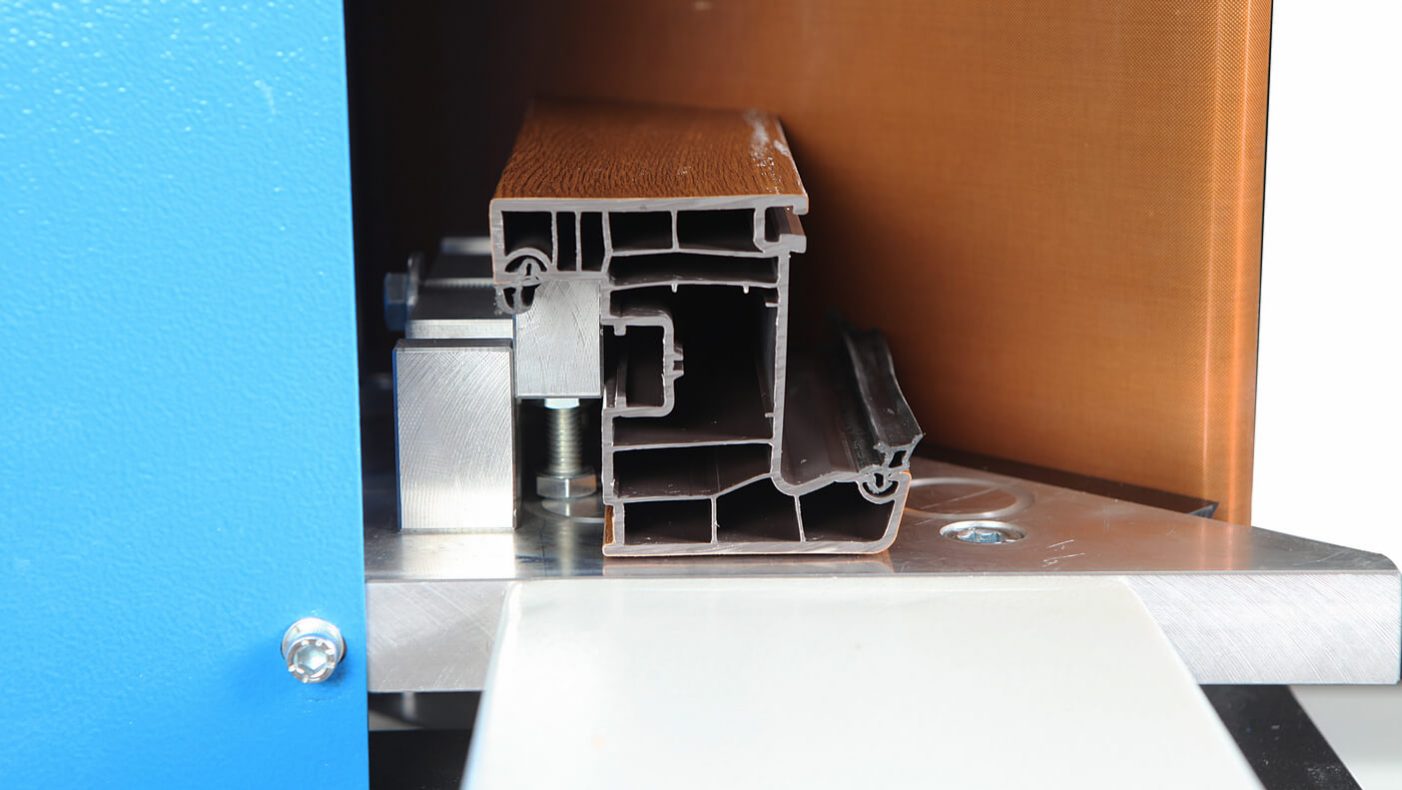

– Teflon coated resistance system, 5 meters of teflon rolls on each head included.

– 0.2mm seamless zero welding.

-Adjustment of heating temperature, welding time and pressure for different kinds of profile

– Easily adjustable calibrated weld patterns are given with the machine.

– PLC control system.

– The ability of welding one corner with a movable head. (This feature makes it possible to weld at different angles from 45)

– It has the ability to weld in the lowest air pressure thanks to its linear system.

– Adjustable supporting arms for profiles

– Heating element has the thermostatic control

– Profile lenght can be weld max: 3000mm min: 350mm

– Maximum profile height can be weld: 175mm

| STANDARD VOLTAGE | 380 V |

| FREQUENCY | 50 Hz |

| TOTAL POWER | 3.8 KW |

| AIR PRESSURE | 6 Bar Min. |

| AIR TRANSPORT | 6 Lt. Min. |

| MACHINE WIDTH | 820 mm. |

| MACHINE LENGTH | 3850 mm. |

| MACHINE HEIGHT | 1480 mm. |

| MACHINE WEIGHT | 520 Kg. |